The use of the term cutting-edge technology is commonplace in UPS industries as well as in other industries.

The purpose of this document is to provide a non-exhaustive overview of what can be considered as innovation that has a bigger impact on efficiency and footprint in UPSs – the three-level inverter.

Figure 1 show the two different outputs of two and three-level converters.

Figure 1 – Phase-to-Neutral voltage in a two-level converter(left) and three-level converter (right)

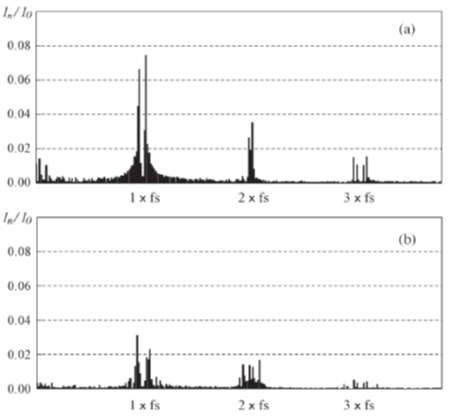

What are the concrete benefits of the three-level wave shape? The most relevant are reduced harmonics (see Figure 2) and efficiency improvements in the conversion process.

Such improvements achieve tangible benefits for users, with regard to:

- compact footprint;

- high UPS efficiency.

Compact Footprint

Considering the THD which can be tolerated by loads at their terminals, it is always necessary to embed a filter just downstream from the inverter, and upstream from the UPS output terminals. Its aim is to transform the square waves of Figure 1 into a sine shape suitable for the load.

The overall dimensions of the filters are proportional to the THD to ’ be removed’. It basically means that a bigger filter is required to supply a load if the inverter is a two rather than three-level type. How much space is saved? It can be up to 30%. Such a saving in volume can directly affect the footprint by reducing it, or it can be used to embed batteries into the UPS rather than increase the backup time of those already provided with internal accumulators.

High efficiency

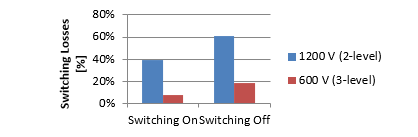

UPS efficiency depends on many aspects, one of which is switching losses. Losses in IGBTs when turning on and off are proportional to the square of the voltage (U2) at the semiconductor terminals. Such dependence is also true for losses in the chokes.

This voltage reduction alone also allows the usage of 600 V IGBTs in place of the 1200 V types required by three-level converters, with the benefits highlighted in Figure 3.

Three-level topology stresses semiconductors and chokes much less than two-level topology, allowing up to 75% savings in such losses due to the converters.

Three-level based UPSs easily reach efficiency levels of around 96%.

How to understand if your UPS is three-level based?

The first and easiest way to find out the installed UPS’s technology is to ask the manufacturer. Unfortunately no legislation currently requires manufacturers to state the topologies used on data plates, except for those commonly known as offline, line interactive and online (more properly named VFD, VI and VFI by standard EN 62040-3).

Various performance levels can be used as a clue to detecting the technology used by UPS manufacturers – efficiency levels around 96%, low footprint, or high backup time, all other things being equal.

Conclusions

Three-level inverter topology is the first tool in the hands of UPS manufacturers to increase efficiency and reduce footprint, fully protecting the load with a real continuous online double conversion working mode (VFI). Every other solution requires a compromise that affects load protection and does not reduce footprint e.g. offline working mode also known as ecomode. This solution supplies loads directly from the mains, exposing them to interference and only compensating outages.

Three-level technology is the only technology capable of ensuring maximum protection with savings in energy and footprint:

- up to 2% efficiency improvement

- up to 30% footprint reduction

compared with previous two-level technology.

Acknowledgements

- K. Sato, M. Kinoshita, Y. Yamamoto and T. Amboh “Redundant High-Density High-Efficiency Double-Conversion Uninterruptible Power System”, IEEE Transactions on industry applications, Vol. 46, No. 4, July/August 2010

Tech Info – April 2011

ARE YOU SURE YOU HAVE A CUTTING-EDGE UPS?

by MATTEO GRANZIERO

Technical Communication Specialist at SOCOMEC UPS